Fiat Uno – The Vehicle From The Future Started 40 Years Ago In The Past

40 years ago, the Fiat Uno really was the vehicle from the future changing the way cars were designed and produced. This compact European hatchback delivered many automotive firsts and what Fiat did ensure a step change in manufacturing quality which everyone else followed.

Extensive research, a massive design and development budget and Robogate, this was a significant investment for Fiat and the development of the new processes made the Uno the car with the best construction quality in its market segment.

Now, we don’t mean quality as in expensive materials, leather on the seats and wood on the dash. In engineering and manufacturing terms, it means minimal deviation from the target spec, dimensions, fit, alignment. panel gaps. I could go on. Take a body panel from a Mk1 Fiesta and offer it up on another, not bad and better than earlier more hand built cars. But with the Uno it would be impossible to tell one from the other. This ability to produce parts that are more alike than before means less scrap, rework and better fit and build than before.

The Uno was launched with great fanfare with its technological innovation to a suitable backdrop of Cape Canaveral in the USA on the 19 January 1983.

The Fiat Uno really represents a step change in the automotive sector with a few firsts. The extensive use of robotics in the production process and a new relationship between design and manufacturing, the Centro Stile and Engineering. Today this is called Functional Design, where everything was designed to meet the highest levels of quality. As the Uno was the most innovative model in the segment this was an important achievement.

There was a large improvement in quality, somewhat due to the large financial investment made. Over five years of research and design, the budget was about one trillion Lire, or somewhere around 775 million Euros today. This was the largest and most significant investment Fiat had made in any vehicle up till that point.

Roberto Giolito, Head of Stellantis Heritage (Alfa Romeo, Fiat, Lancia, Abarth) stated that:

“The Uno was a completely innovative project, starting with its body which, unlike its 127 predecessors, was designed to be made with robotic welding.”

“The same doors were assembled with fewer components and the new tailgate also removed the weld line which previously had been perceived as a flaw and now had become a distinctive design for the side.

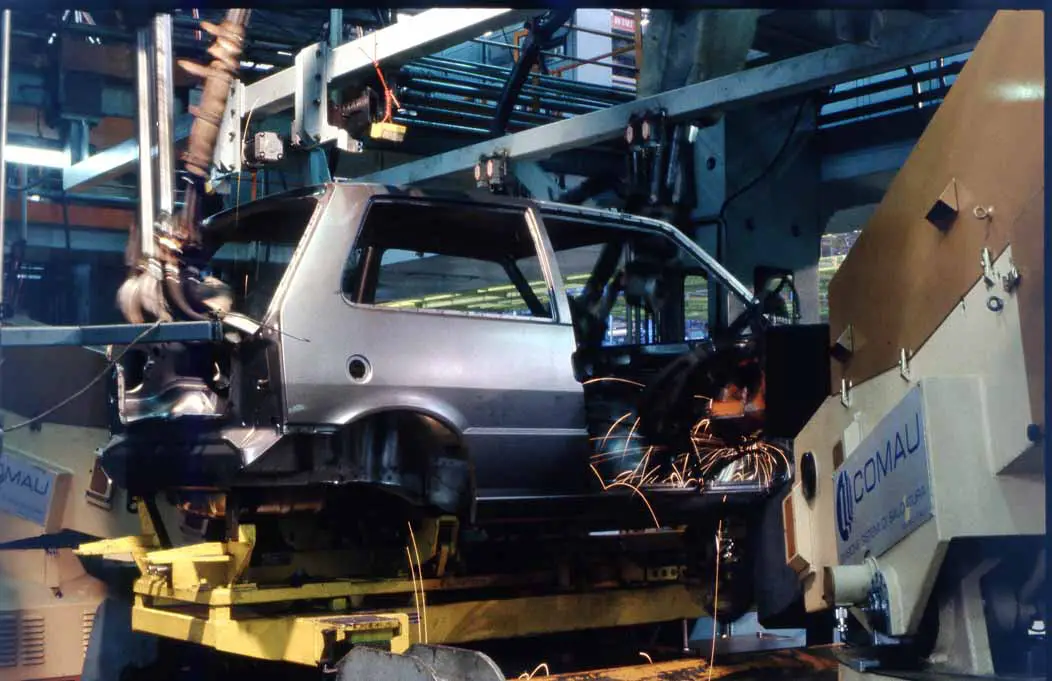

Robogate - Car Factory Automation

A new concept of production developed with the Uno leading to an integrated factory with greater flexibility. Underpinning this was Robogate, a highly sophisticated production system designed by Comau, a leading automation company for the assembly of car bodies. This was mainly based on the spot welding of each individual piece of the car.

This new system made its debut in 1978 at the Rivalta factory with the Ritmo but was soon employed at the Mirafiori and Cassino plants.

The Fiat Uno made use of this system and made use of dozens of robots for the assembly, welding and body coating phases of assembly. This significantly improved the uniformity and quality of production.

A significant part of the investment made by Fiat in the Uno was the factory automation. Each day the robots would perform a spectacular “dance” with mechanical arms, lifts and gates, with timing and processes managed by computer.

“The Fiat Uno was not only part of a manufacturing revolution, it changed the entire way of conceiving, developing, and producing a car. From the CAD design desks to the factory, everything became part of a continuum and managed by a single system,” stated Giolito.

“If today dedicated networks and hardware connections link various areas of the plant, tomorrow it will be the concept of the “Internet of Things” which will rule and create a dialogue between these machines to reach the greatest flexibility possible. This will allow for the construction of cars for every continent and culture in the most efficient and sustainable way possible.”

The FIRE Engine - Fiat’s Technological Success

Fiat built a futuristic new factory, Termoli 3, which was specifically created in 1985 for the construction of the new FIRE motor. This has a history closely connected to the Uno as it was the first car fitted with the new Italian engineering gem. Produced for 35 years and with over 23 million of them built.

FIRE stood for Fully Integrated Robotized Engine and referred to the manufacturing method, the Robogate system. But that was responsible for making the engine more compact and lighter, only 69 kg, with the simpler design using 95 components less than the predecessor. More modern with a single overhead camshaft, no more rods and rockers, and more reliable and easier to assemble. This was a very long lasting project and became known for its reliability and quality and was one of the best engines Fiat have ever built.

Vehicle Engineering Gamechanger - Stellantis Heritage Video

Roberto Giolito, Head of Stellantis Heritage (Alfa Romeo, Fiat, Lancia, Abarth), takes viewers on this journey with images from the Centro Storico Fiat and memorabilia conserved at the Heritage Hub, which can be visited by booking a guided tour here.

The Uno brought in a revolutionary way that vehicles were designed. Drafting tables were repaced by CAD, Computer Aided Design, stations.

This allowed tolerances to be reduce to as close to zero as possible, a part of manual design that was always sucseptible to some human error. But not jsut that, the relationship between the Centro Stil and Enginering functions changed. This allowed for more close collaboration and combined they looked for solutions combining design with function and aesthetics with rationality.

During this period Guppe Fiat were happy to show off common components or modular parts which were used to make vehicles and for other brands too.

At the beginning of the 1980s Fiat’s Centro Stile became studio for the whole groups brands due to the style coordination of the Group’s brands and played a greater role in technical management, or Engineering Management as we know it today.

Central Stile had a constant dialogue with many body shops at the time, including the newly formed Italdesign of Giorgetto Giugiaro which designed the Fiat Uno, Bertone, Pininfarina, and eventually Idea Institute studios.

The Beginning Of Functional Design

The Fiat Uno was ahead of the European competition in the style of offering a body style where the windshield which leaned more towards the front, as if it had a “single volume” form.

An increased slope of the hood, or bonnet, almost united the front window with it. The rear window was now completely flush eliminating the rain gutter above the door for the first time. The factory robots enabled the roof welding to be done with suspenders allowing for greater access and ease in entering and exiting the car. The drivers eat could be raised a few centimetres and the Uno was giver greater road control and manoeuvrability in a small package.

The Fiat Uno was launched in 1983 and almost became an immediate success. It was very well received by the market with strong sales and the media professionals voted it as Car of the Year in 1984.

The large cabin which could accommodate five people and still having a decent trunk volume which was easily accessible from the large hatch opening.

The Uno had an innovative dashboard with two knobs on the sides of the instrument panel where nearly everything could be controlled. Only the turn signal used a conventional switch behind the steering wheel, while the climate controls were located in the centre and under the air vents. Externally the front featured an effective single windscreen wiper which was fitted with an intermittent control and various speeds.

Roberto Giolito concluded by stating that:

“The Fiat Uno is an archetype which was copied by many competitors and paved the way for them to introduce their products. However, Fiat would continue to be the clear leader in this segment, so much so that an electronic-induction turbo version would break ground for compact yet sporty hatchbacks.

Ford’s Heritage Vault Makes The Ford Times Magazine Available To The Public

Ford’s expansion through the early 20th century was something to behold, the rapid growth of the company and the success of the Model T led

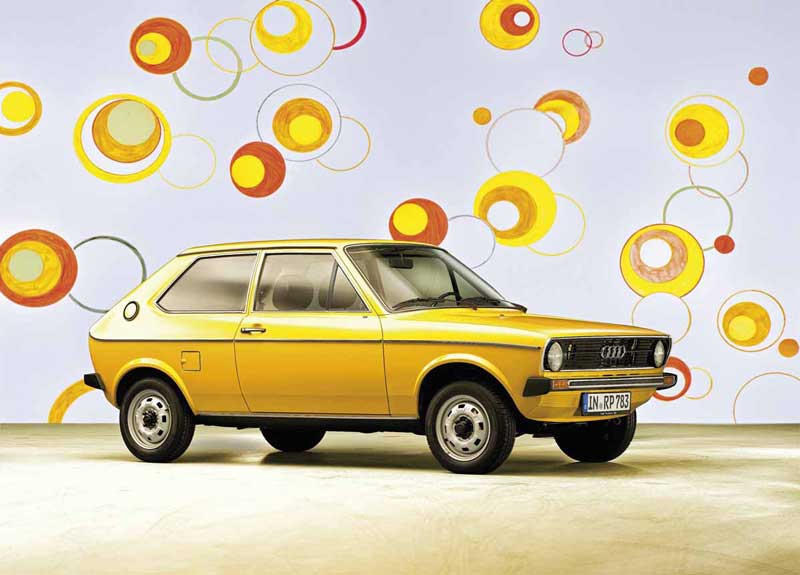

The Audi 50 At 50, Germany’s First Small Car

The Audi 50 that was the basis for the VW Polo is now 50. The small car was developed ahead of the oil crisis of

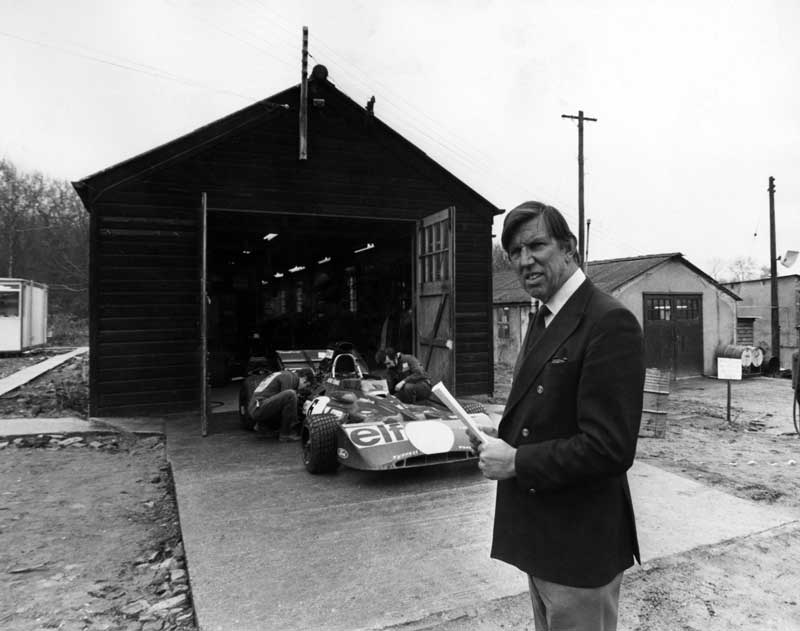

The Best Things Happen In An English Shed, Especially The Tyrrell Shed At Goodwood

The Tyrrell Shed once home of the World Championship winning Tyrrell Formula 1 team has been relocated to Goodwood and is set to open for

A 1973 Ferrari 246 Dino From The Manager Of Rock Legends Led Zeppelin Sold At Auction

Something of a piece of rock and roll history went for sale with the auction of Led Zeppelin manager Peter Grant’s old Ferrari 246 Dino

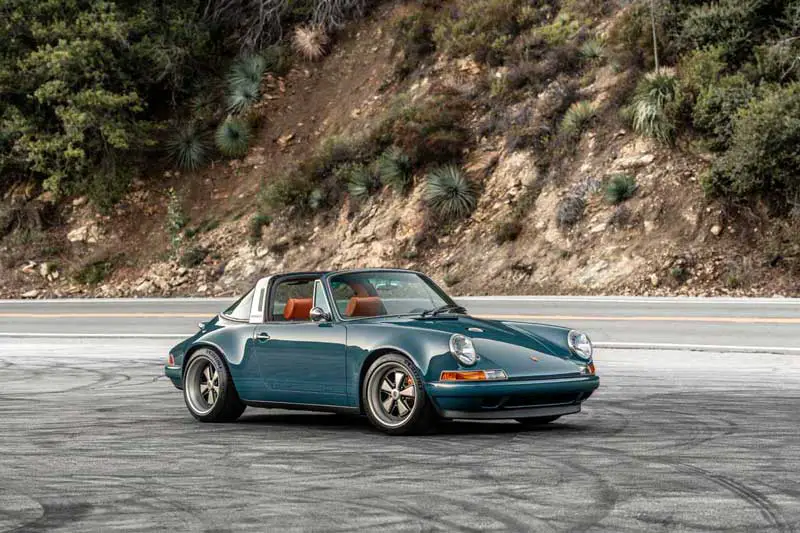

California Based Singer Has Completed Its 300th Restoration, The Sotto

Restomodders Singer have produced their 300th 911 already and it’s another964 based conversion called the Sotto. It’s almost hard to believe it was a964, though

The True Spirit Of The Jaguar XJ13 Presented By JD Classics At Retromobile 2024

The masterpiece that is the Spirit of the XJ13 is unveiled at Retromobile 2024 by JD Classics of Chelmsford, England, and seen for the first