Can You Use a Torque Wrench As a Breaker Bar?

Can you really use a torque wrench as, or instead of, a breaker bar?

The short answer is no, as you can cause quite a bit of damage to them. Read on to learn about the differences between the two and whether you can use the breaker bar instead of a torque wrench.

Table of Contents

What Is A Torque Wrench?

A torque wrench is a precision tool designed to help you do up nuts, bolts and other fasteners to a pre-set value and no more. using one is the best way to guarantee a set torque that you need to apply.

This is important as each faster with its own material type and grade has a maximum amount of torque that can be applied to it.

There are six types of torque wrench, although you’re only likely to find five of those for sale in your favourite tool store.

How Does A Torque Wrench Work?

A torque wrench works by providing a specific torque to a screw, a bolt or even a screw.

The handle of the torque wrench will usually have the torque value marked on a calibrated scale which can be pre-set. The indicator, be it a click type, a digital or a beam, will tell you when you have applied enough torque. Don’t go over that as you may damage your torque wrench. Especially those with a main spring inside which can weaken and loosen over time.

Being a precision tool means that a torque wrench should be handled and stored correctly. If it gets damaged, then it can lose its effectiveness and not give you the correct torque. Too much and you’ll break bolts. Too little and things can fall off.

It’s also a good idea to get them checked fairly regularly, so they can be adjusted or rebuilt, if they allow for that.

What Are The Different Types Of Torque Wrenches?

There are really only six types of torque wrench.

Click type, digital, slip type, beam type, split beam and intelligent. Now you’ll only need to be concerned with the first five and each one has its advantages and disadvantages.

Latest Articles

Workshop

Click Type Torque Wrenches?

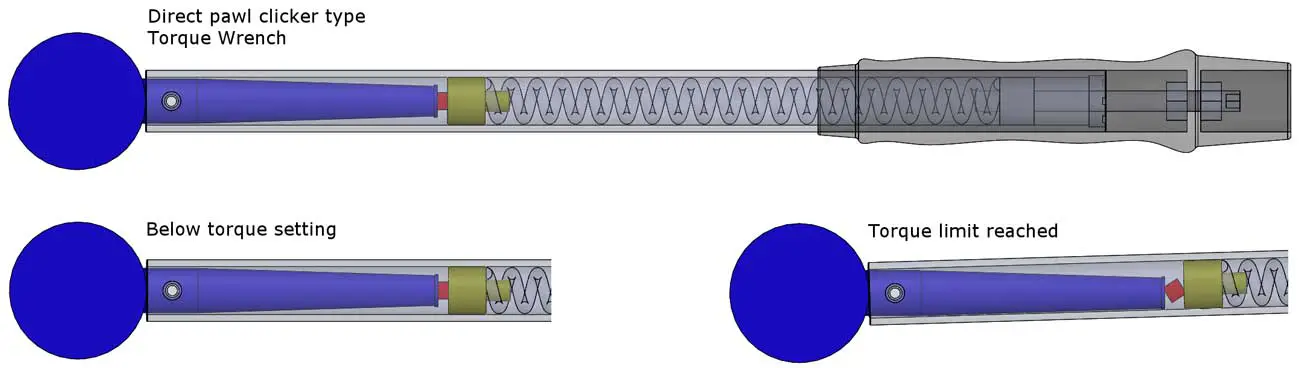

The most common is the click type which is purely mechanical. These are readily available and can be cheap, although you can get better quality with a higher price. For the home amateur it may not be necessary as the accuracy of those cheap ones can be very good.

The click type works by setting the torque value at the handle with the adjuster nut to the desired value on the calibrated scale. Then tighten the nut and wait for the click.

The main downside with this type is that it will not prevent over tightening and if you do continually try to over torque with one, you will weaken the spring and it will go loose inside and the click arm will not click at the right torque and your bolt will not be set to the right value any more.

Digital / Electronic Torque Wrenches

Any digital or electronic torque wrench is going to be more expensive than a mechanical one. They are among the most effective types being able to store several pre-set torque values and they most often have an audible signal.

Otherwise they are similar to the mechanical type, so if you want to save time and store several values then they can be very convenient. If you’re using one regularly then why not, the extra cost may be worth it.

Slip Type Torque Wrenches

Slip type torque wrenches are relatively simple, but so effective. They are designed to lose grip as they reach the desired torque level, they work on a friction principle and lose the drive to the socket.

This is where their main benefit comes in, they prevent over-torquing.

The downside, well you can’t monitor the torque as it is being applied. But you don’t necessarily need to do that, if you’ve set the torque you need, just slowly build up to it.

They are limited to maximum torques however, typically this is 100 Nm.

Beam Type Torque Wrenches

The beam type torque wrench may appear old fashioned, and they are to some extent, but they are just as good as the other types. The main benefit is that there is no need to pre-set the torque as it can be seen as you turn the wrench.

The downside is that in some instances it can be difficult to see whilst you are using it, especially on bigger torques requiring a lot more effort. But for when you can get those parts on the bench these are great. Fast to use and cheap to buy. Everyone who works on their classic car or motorcycle needs a torque wrench and they should have one of these too.

Split Beam Type Torque Wrenches

A split beam torque wrench is a simple but more robust beam wrench with fewer parts than a clicking type of torque wrench. Not only that most of them have been welded together making it much more robust.

This type of torque wrench is designed to last longer than a click type and to be more of a professional kind of tool. though if you’re a heavy user one of these should be considered.

The split beam name comes from it having two beams. One is the handle, which is far stronger than other types, and the other end has the head.

A good one will have an indicator window and a click too. Look out for these.

Intelligent Torque Wrenches

The way these work is a bit like a digital or electric torque wrench, but they are programmed centrally and can be updated on the fly. They know from the type of fastener they are tightening what torque value then need.

Brilliant, but too expensive and totally unnecessary for home use. Unless you’re planning of making your own production line of course.

Torque Wrench Sizes

Torque wrenches come in all the standard sizes you get for sockets and wrenches.

- 3/8 inch: The smallest size used in repairing cars or motorcycles. these are ideal for using with low torque applications where you don’t want the extra weight or bulk of a 1/2 inch drive. they make for easier access and is probably the most popular size. It’s the smaller threads that get stripped the most often.

- 1/4 inch: This is really well suited to motorcycles and small fasteners on cars.

- 1/2 inch: The standard size for wrenches and sockets. Torque wrenches in this size are best suited to bigger torques, lug nuts, shafts and suspension bolts.

Bigger than that and you’re probably working on farm machinery or some pretty large industrial equipment and isn’t really needed for the levels of torque you’ll come across with your classic car or motorcycle.

What Is A Breaker Bar?

A Breaker bar is one of the simplest tools you can buy. Its sole purpose is to give you a mechanical advantage with the extra length over a wrench. This means you have more leverage and can apply more torque to undo those stubborn nuts.

They come in all the different sizes that you get wrenches in, though you’re really only likely to need the larger type for those nuts and bolts with bigger threads. If they are really stuck those smaller ones can snap, then you’ll have another problem.

Can You Use A Breaker Bar As a Torque Wrench?

No, they aren’t meant to be used in that way. It doesn’t mean that you can’t do up nuts and bolts with a breaker bar, you just won’t be able to control the torque. So, a breaker bar is not a good tool to use to do up bolts and get it right.

Torque Wrenches Vs Breaker Bar Verdict

Can you use a torque wrench as a breaker bar? You can, but it is not recommended, I certainly don’t advise it.

With the price of breaker bars being low then it doesn’t make sense to risk it. But theoretically if you are under the maximum torque, it should be ok. I just don’t do it.

No, they aren’t meant to be used in that way. It doesn’t mean that you can’t do up nuts and bolts with a breaker bar, you just won’t be able to control the torque. So, a breaker bar is not a good tool to use to do up bolts and get it right.