How The British Managed Volkswagen From 1945 – 1949 & The Return To Production

75 years ago, the British Military Government managed Volkswagen for a period of four years from 1945. The remains of Volkswagenwerk GmbH were placed under the control of the British, who were in charge of getting production back to the Wolfsburg plant. This four year stewardship ran from June 5, 1945, until October 8, 1949, replacing the US troops in the region.

However, there was no certain plan for the factory except for demolition. Allied bombing had caused a great amount of destruction to the factory, and it wasn’t clear that it would be salvageable.

One man saw the potential and is credited with saving it from destruction. 28 year old Major Ivan Hirst was sent to Wolfsburg to take charge of the remains. He saw an opportunity that many others hadn’t. The need for the British Government to be mobile around Germany and the need for Germany to develop into a self-sustaining nation. This moved Hirst to save the plant so cars could be made, which would suit both purposes. This aligned with the overall British Government policy for Germany.

What might seem strange is that the British were responsible for laying the foundation for today’s Volkswagen Group. Especially as there aren’t many competitors in Britain any more… The success of the Beetle has a great deal to own the British and Hirst. Something of a unique post war story.

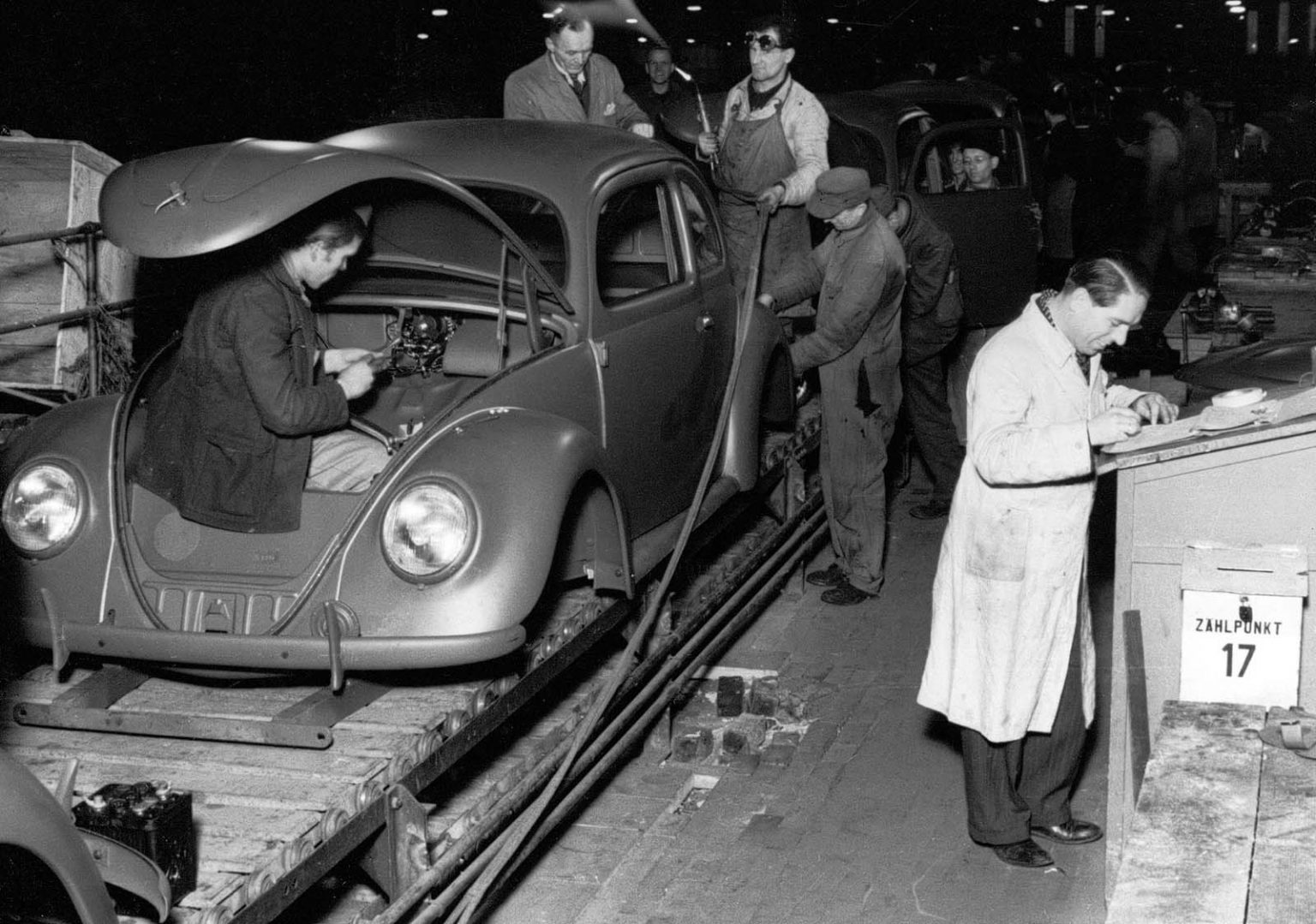

Hirst is the key figure in this, a man with many talents. Improvisation, organizational capabilities and tremendous farsightedness. Hirst reshaped the remains of the largely destroyed armaments plant, which was intended for demolition, into a civilian car factory.

The end of the Second World War saw Volkswagenwerk GmbH lose its owner. The National Socialist organization Deutsche Arbeitsfront (German Labor Front) no longer existed. The plant was planned by the National Socialists and a flagship factory for the production of the KdF-Wagen. During the war it produced military goods and armaments. There were some 20,000 forced labourers used during this period.

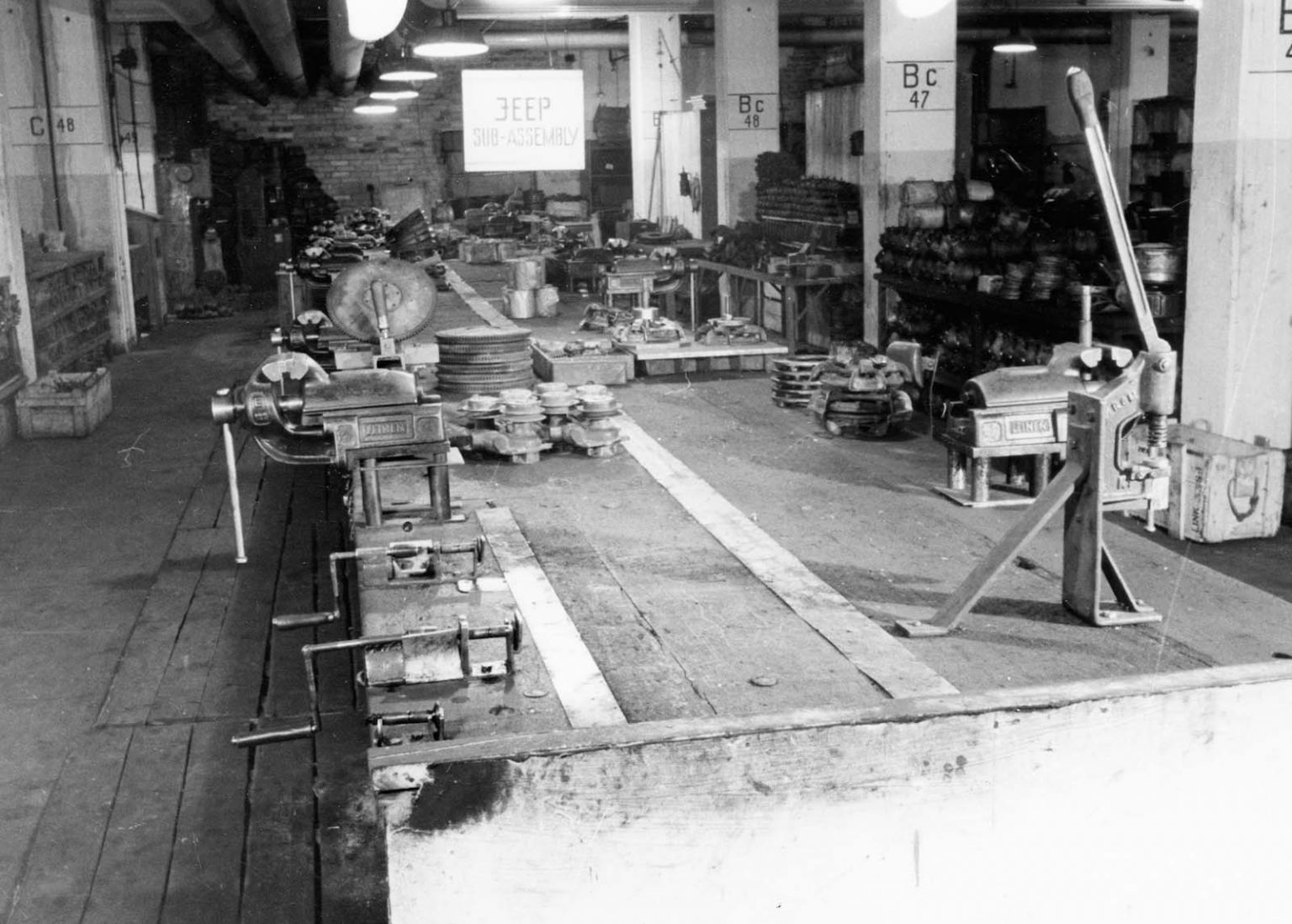

Being a former armament plant, it was initially scheduled for demolition after the war. But after liberation, the American forces has built a workshop there. When the Americans withdrew the plant fell into the ownership of the British. Major Hirst was sent to Wolfsburg and the senior Resident Officer he assumed the responsibility for the plant. He very quickly saw the potential use for the factory, far more than a simple repair shop.

Volkswagen And The British Era

Shortages, Harvesting and Volumne Production

“Initially,” Ivan Hirst begins his Volkswagen story, “my brief was very simple. Go to Wolfsburg, find the factory and sit on it. They didn’t even say it was a Volkswagen factory.”

Major Hirst arrived in Wolfsburg in August 1945 and was satisfied when he took his leave four years later in August 1949: “There was a modern factory, ready to go, with a labour force, a German management and a product that was proven,” Hirst remembers. “And when the currency changed in 1948, it took off: Volkswagen went round the world.”

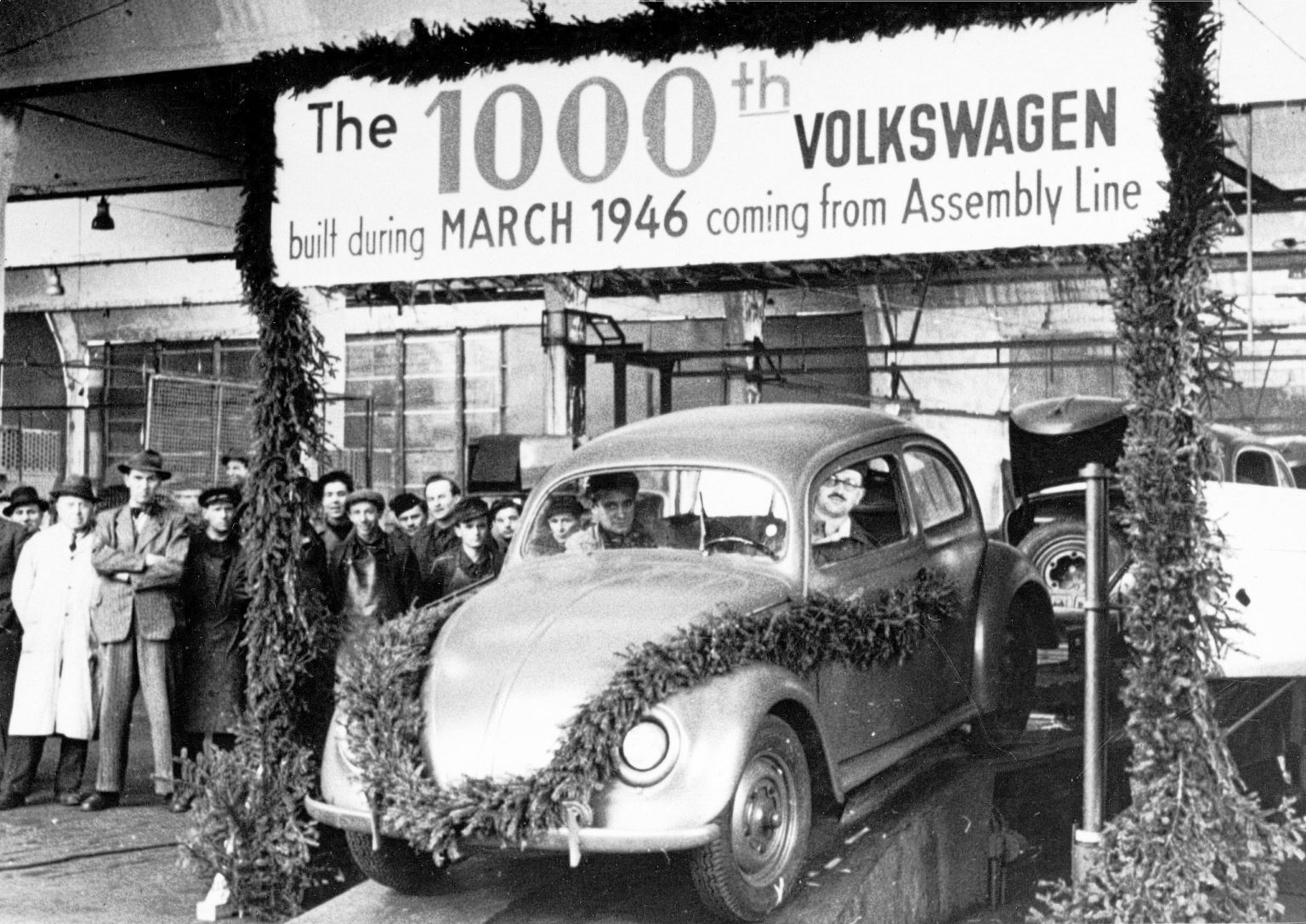

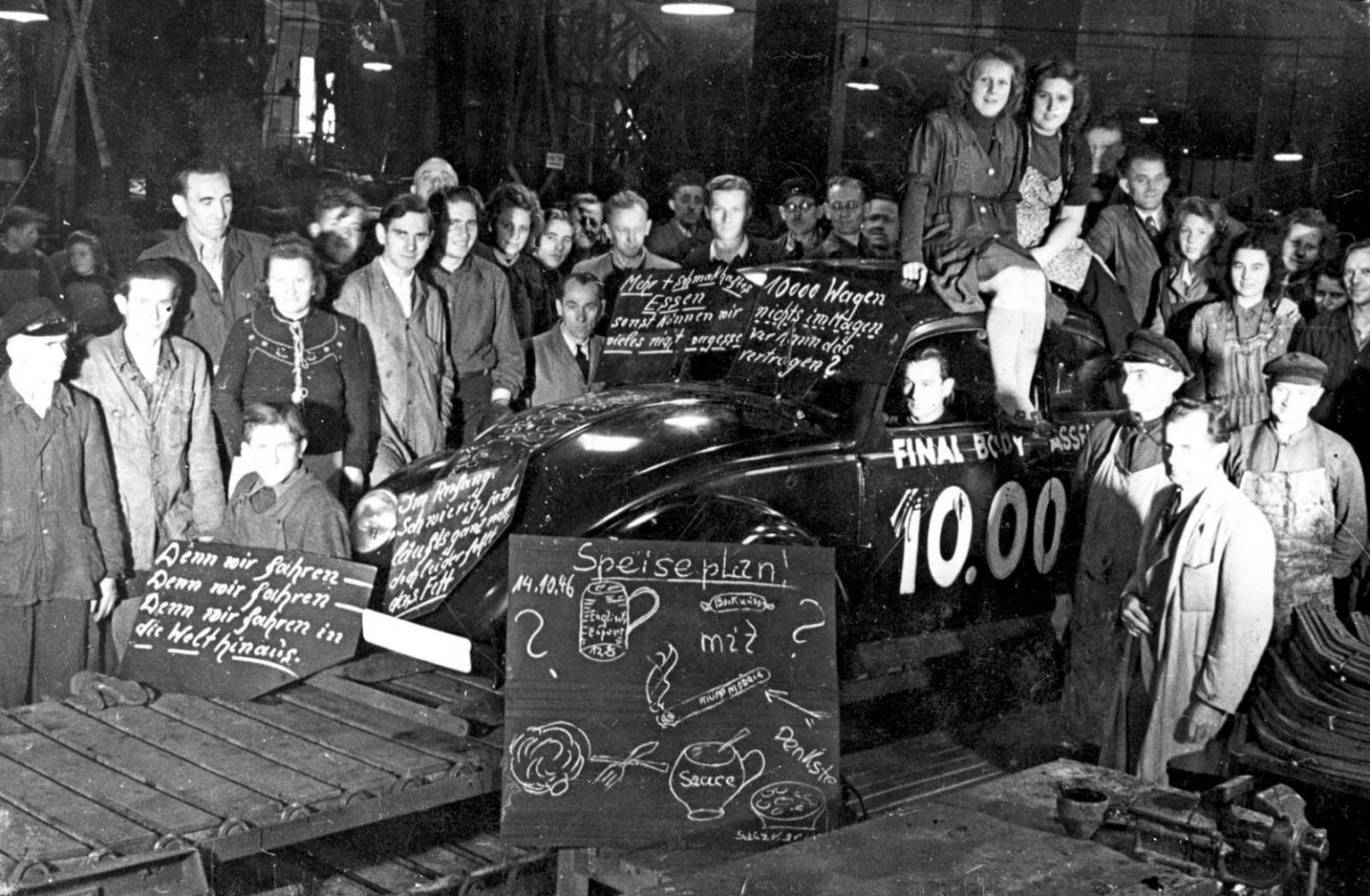

Even though materials were scarce there was enough to produce the monthly target of 1,000 vehicles. This was reached in March 1946 for the first time. The workforce was small, recruiting more was difficult. But Hirst was pragmatic and offered jobs to German prisoners of war.

Food was also in short supply, but Hirst managed to organize supplies through his contacts along with other items. They even had a harvest of crops around the plant. Hirst authorised the planting of cereal crops around the factory buildings. Even with these measures, the workforce wasn’t always happy as they were sometimes left hungry.

In October 1945 the first freely elected world council was formed. One of the things that was seen to be a step towards democratisation. The main task of the representative body was to ensure shortages were distributed fairly.

The Handover To Germany

As the prospects for the future seemed good, the British trustees decided to transfer the management of the plant to an expert and return it to German control. Heinrich Nordhoff was appointed managing director with effect from January 1, 1948. Only three years after the war Volkswagen had been turned around from a ruined armaments factory to a functioning car plant with 8,700 employees.

June 22, 1948, brought the real turning point. The currency reform started something of an economic boom in the three occupied zones. This meant that things were moving in the right direction. On October 8,1949, the British Military Government transferred the trusteeship of Volkswagenwerk GmbH to the German government.

Documentary “My brief was very simple” The British Era At Volkswagen From 1949 - 1945 Narrated by Ivan Hirst

Ural Ataman Classic Car Museum – Istanbul, Turkey

This has to be one of the nicest private collections I have seen, the Ural Ataman Museum in Istanbul, turkey has not only a wide

Tbilisi AutoMuseum Car Museum – Georgia

You may not have heard of this, but the small car museum in Tbilisi Georgia really has quite a lot to see. Buried in an

Bahrain Bike Week Classic Car Show December 2024

Bahrain Bike Week is the biggest event of its kind in the Middle East and the 2024 one was no exception. It’s not just the

Ford Motor Company Bring Back Group 5 Mk1 Escort & Group B RS200 With The Help Of Boreham Motorworks

Ford have granted a licence to Boreham Motorworks, a division of the DVRN Automotive Group, to produce new versions of not just the Mk1 Escort

The VW Golf At 50 Years Old

Europe’s number 1 selling car the VW Golf has reached 50 years old this year, starting production on the 29th of March 1974. In

Ford’s Heritage Vault Makes The Ford Times Magazine Available To The Public

Ford’s expansion through the early 20th century was something to behold, the rapid growth of the company and the success of the Model T led