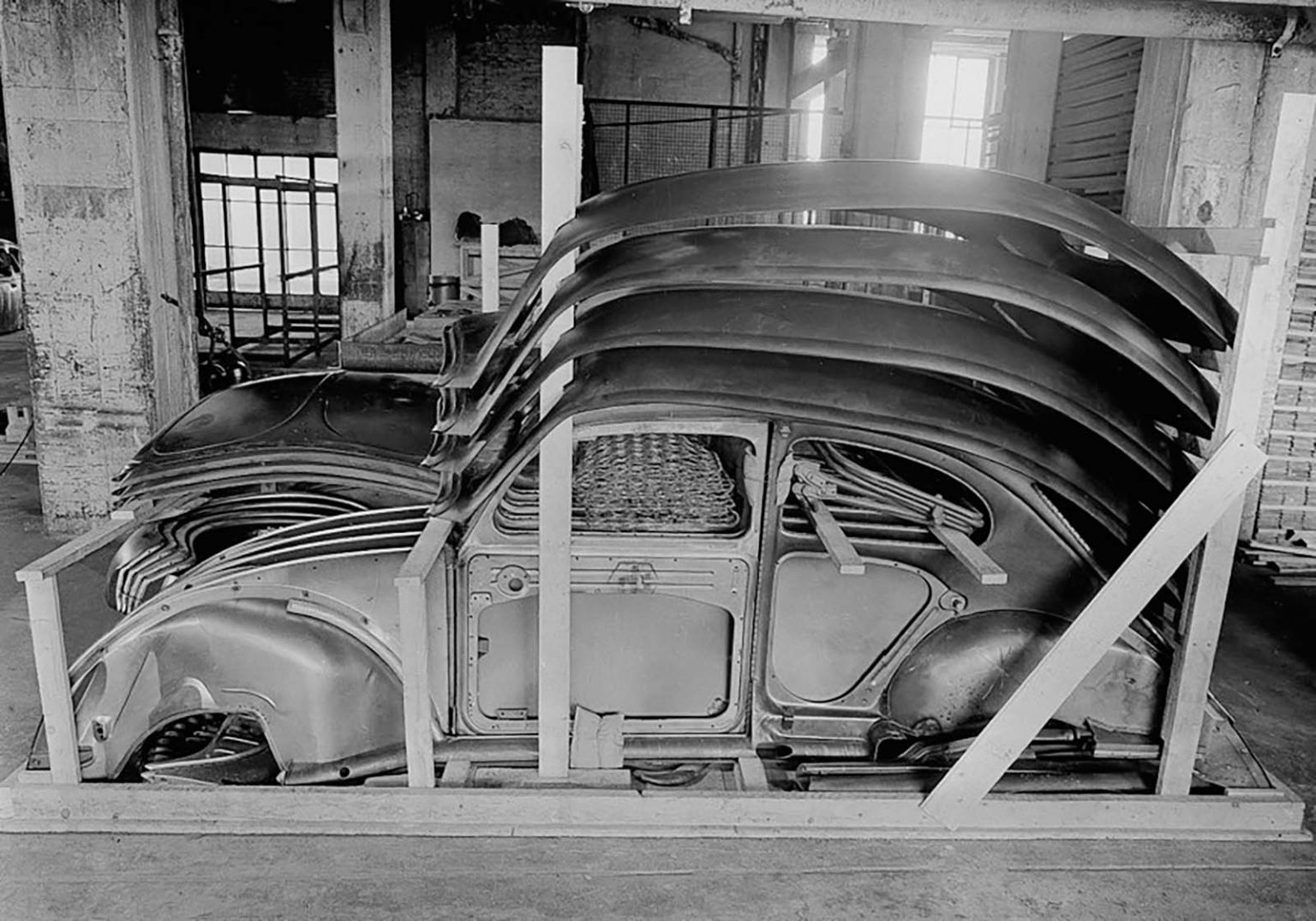

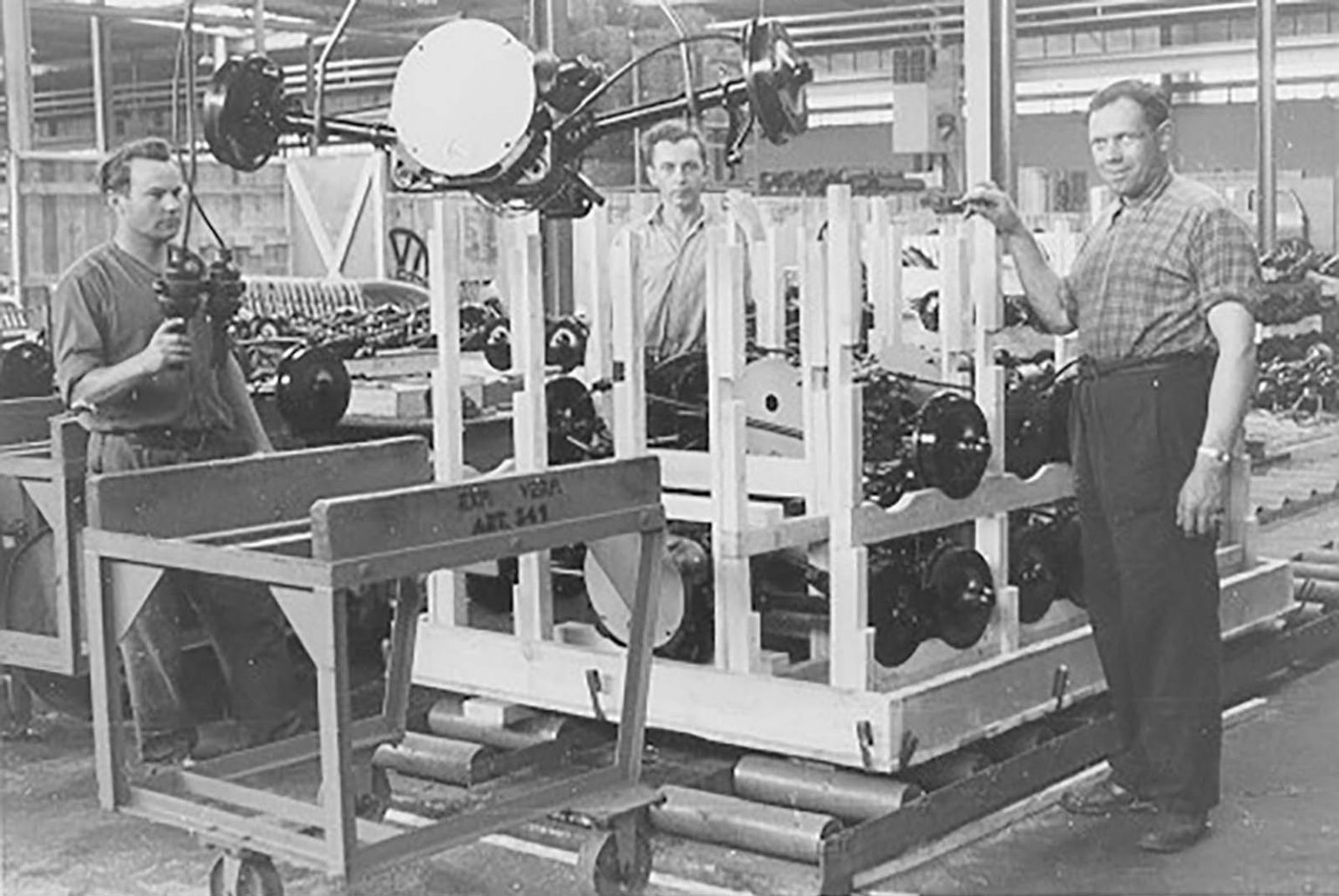

VW have been exporting CKD kits for 70 years, starting with the Volkswagen Beetle. The Completely Knocked Down kit is a whole car broken down into a series of parts to assemble. Just like a model kit, only bigger.

Since 1950 Volkswagen have been supplying kits to other countries. This was to get VW products into emerging markets and grow global production. Some 25,000 overseas containers are shipped to 10 countries and 27 locations every year. This equates to about 200 million vehicles that have been exported to date.

These days the used of CKD kits is a way of ensuring supply to Volkswagen’s global production network. This plays a key role in sales. Some 3 million further vehicles or parts are added every year to this process.

Of course, the first vehicle to be assembled from a box of parts was the legendary Beetle. It isn’t always viable to build a complete car factory in some countries. Volumes may not be high enough for the country. The tooling costs could be too high. Not to mention customs and import regulations.

The first Beetle kit in 1950 was delivered to be assembled in Ireland. Following this, boxes started arriving in South Africa, Argentina, Brazil and Mexico. Central and South America are synonymous with the Beetle and the volumes were quite substantial. Mexico even ended up exporting the Beetle back to Europe when production ended in Germany.

If you’ve ever been to Central or South America, you’ll have seen the amount of them that are there. Still on the road even today. Mind you, they did make them up to 2003 as a 2004 model in Mexico. In Brazil they had a gap from 1986 until 1993 and managed to get to make them up to 1997.

The largest of the CKD plants is located in South Africa. Currently the Polo for all right-hand-drive markets is assembled there. Just like the Beetle, European models are produced outside of Germany. There are further plants located in the USA, China, Brazil, Argentina, India, Malaysia and Indonesia.