Static Fleet Update – Probably Permanently At This Rate

The Trabant is a great little car, except when it’s a driveway ornament and then a garage one. At least at 600kg you can push it on your own… even uphill.

With an impeding house move I decided to get it running so I could drive it away, why not it will be good to have it back on the road again and will make a great shopping car. If I can get it working.

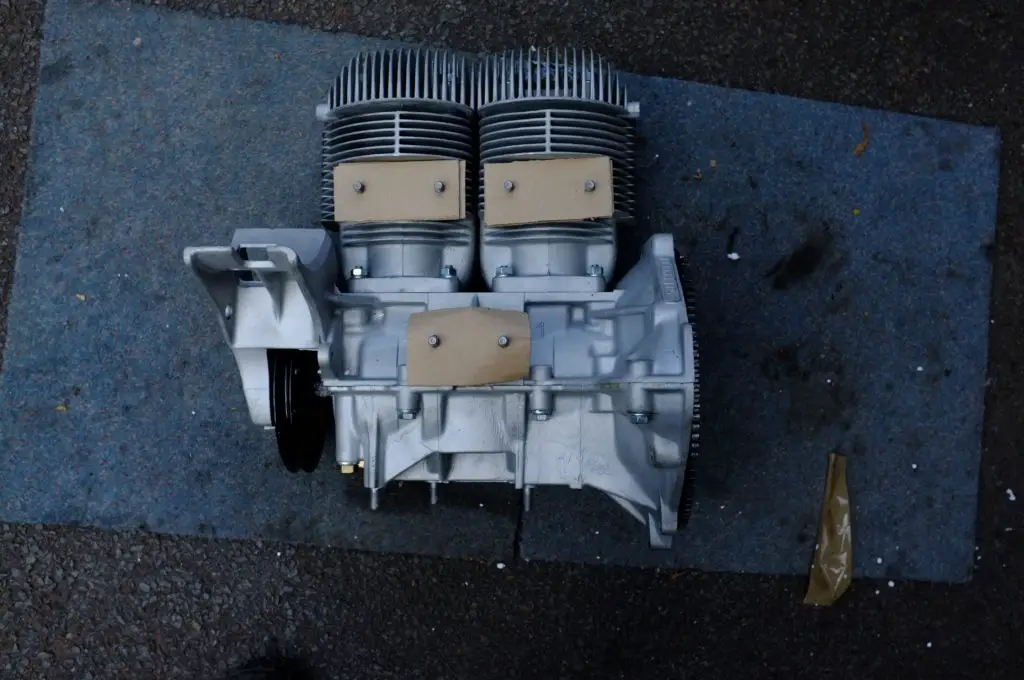

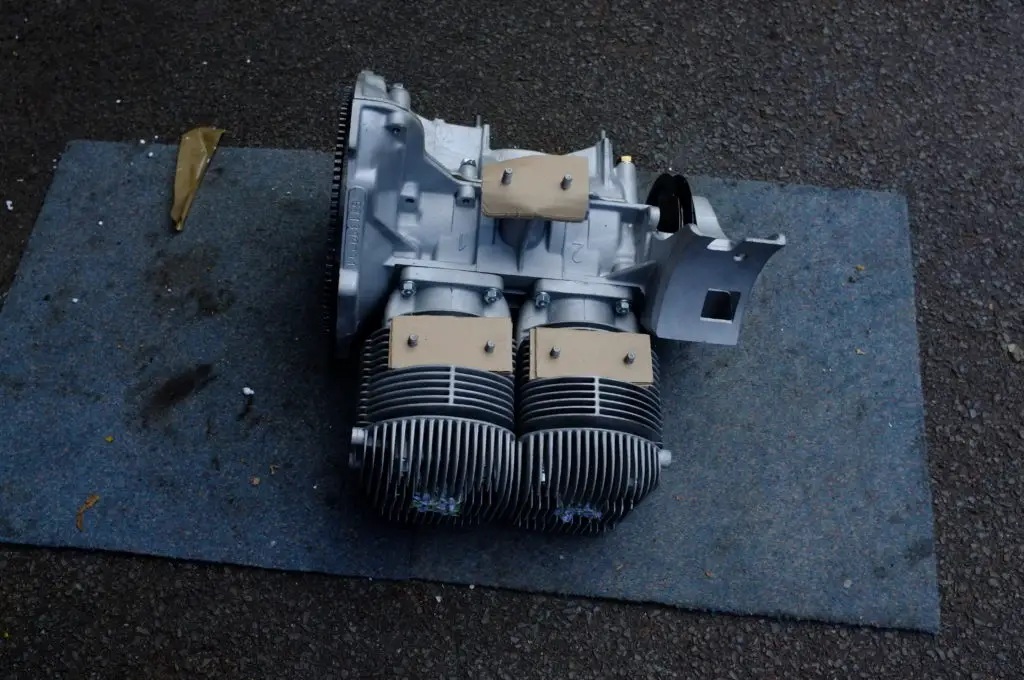

I managed to meet a nice lady by the name of Sheila who sold me her new, reconditioned engine and gearbox by LDM Tuning of Germany. I though this should be straightforward enough to make it run and drive away. So I set about getting things prepared, not to mention clear enough space to actually do it. So with a lot of rubbish moved out of the garage the Trabant was pushed in.

Notice the other new Jalopy feature in the other side….

Stripping the Trabant wasn’t terribly difficult, most things only having up to three bolts holding it in.

The Trabant having something in common with modern cars, the engine is hidden underneath a cover although this is a heat shield and thermal jacket, so isn’t there just to make it look pretty. It doesn’t.

Getting the engine out was a bit of a pain as I wasn’t going to separate the engine and box in the car not remove the any of the suspension or the hubs. I did enlist some help, Georgia, a fifteen year old girl who proved rather adept and Trabant work.

Except this was great, the tripod bearings on the end of the driveshafts do not have circlips holding the bearings on, so they fell off dropping needle rollers all over the place… I didn’t find all of them with the telescopic magnet. Not to worry, some new ones would be ordered along with some new bits I needed. I should rephrase that, I now needed as all I should have done is stick the carb back on and run it, somehow I managed to find all sorts of things that it should have.

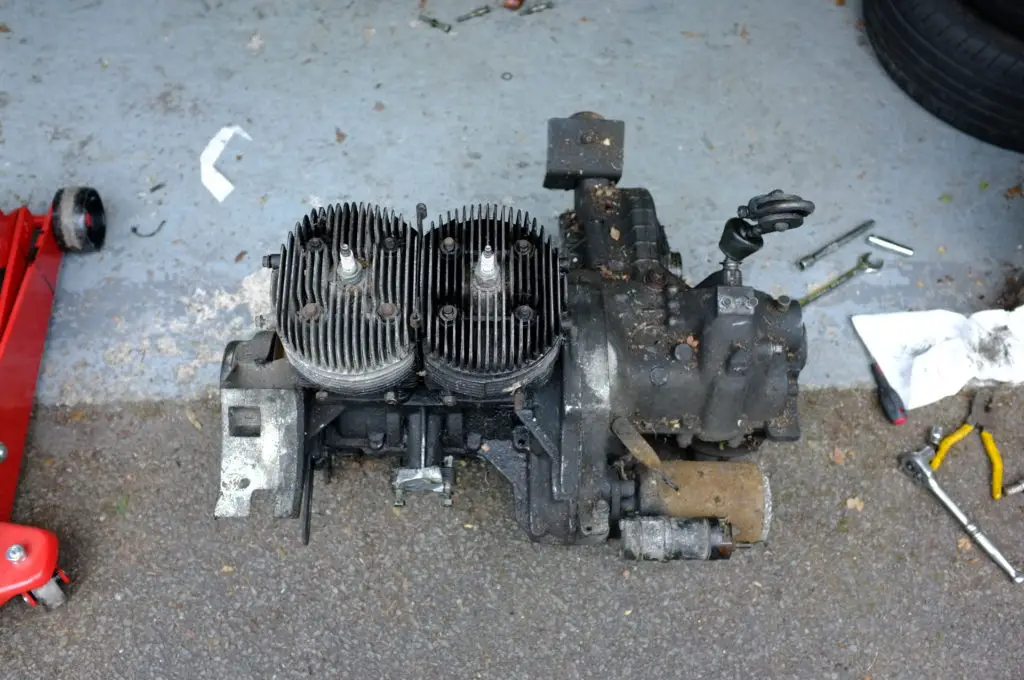

The engine separated from the gearbox easily enough, showing the simplicity of the arrangement inside.

I’d have to re-use that clutch as I couldn’t find a suitable replacement and I wasn’t about to pay £140 or so for it’s replacement, it’s only a 160mm friction plate I wanted, shouldn’t be that hard to find one.

I placed orders for parts and got on with other things, like sorting out the tarnished reflector in one of the headlamps by trying to get them out. Easier said than done…

I thought it would also be a good idea to replace the fan bearing, its noisy around the engine so anything that helps quieten things down so I can actually hear mechanical noises I might need to can only be a good thing.

So I got my pliers out an promptly broke the circlip into three pieces… and then no amount of pulling with an unsuitable tool was going to separate the pulley from the shaft.

Next up I had to get the old ignition pickup housing off the old engine. Now this didn’t want to part company with the old crankcase, it was well and truly stuck. Including the two little screws holding it on. So out comes the drill, to attack them with.

Now remember I said I had placed an order for parts, well guess what I didn’t think I’d need…. yes you got it, the screws, more on this later.

In the meantime many things had arrived, including enough stuff to assemble the brakes, I’d already made the pipes so should be straightforward.

One nice new master cylinder, I figured I wasn’t going to spend time rebuilding the old one, unfortunately they forgot to include the new brake switch which was a bit frustrating.

All fitted and eventually bled and working well.

For some reason the drivers door lock had become stuck and the door wouldn’t shut. Turned out to be a stuck rod, so some lubricating and another thing now worked. Which like the brakes worked before I took any of it apart.

Reassembling the tripod bearings with new needle rollers was time consuming, especially as they don’t want to stay on the ends of the driveshafts when you are trying to put a gearbox in.

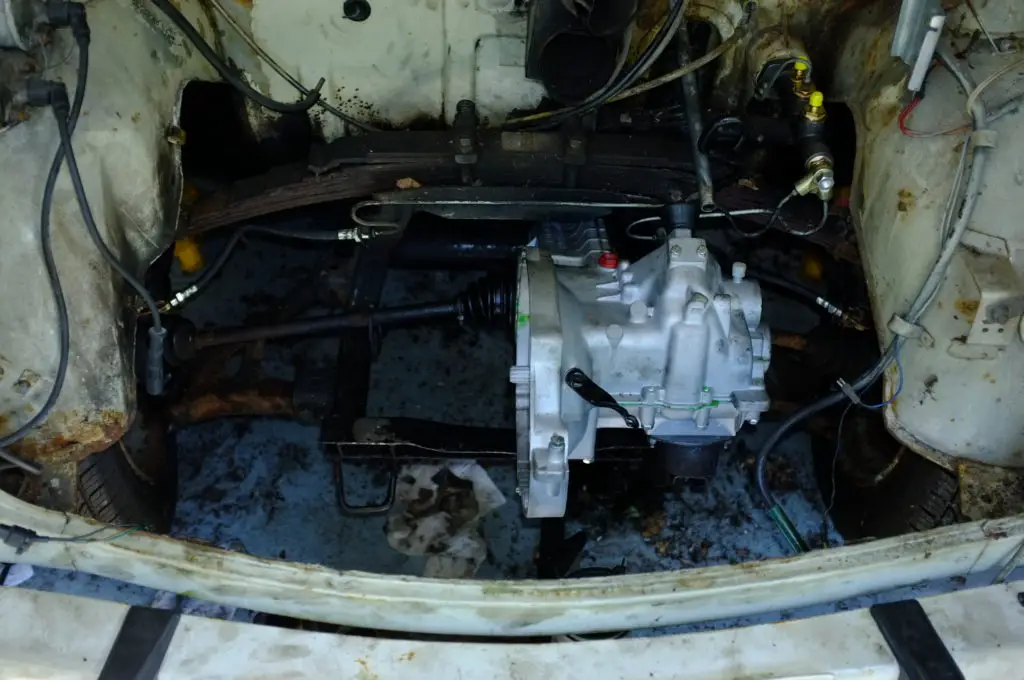

And one nice new gearbox, fitted with the help of Georgia.

This was the time to unpack the new engine and align the old clutch, with my index finger…

This was going too well, the engine slotting in nicely with a few bolts and the starter put in place to check things were aligned and working. I had a working clutch and no gears, well one that I was stuck in. For some unknown reason the new box was jammed, I had no idea which one, this was purely academic as it wasn’t going to get running like this.

So, the nicely installed combination had t be removed and the original gearbox complete with leak put back, on my own.

Oh well. At least now I had the majority of a working car, the carb going back on, the fuel system plumbed back in. Except, the ignition timing… Yes, concealed within the pickup housing that needed the two screws I hadn’t ordered. Well I was stuck in Mexico for a couple of weeks and the Sunday after I returned was get the Trabant running day. Well, it still hasn’t happened and I resorted to a rather good plan B option, why I didn’t call Adam in the first place is beyond me.

Failure was quite satisfying in the end.

Simon