Bentley have produced the first new Blower 4 1/2 litre car in over 90 years. The last original one produced in 1930.

Car Zero as it is known is the first of the continuation series of the Blower, of which there will be 12 built for customers. This is also the world’s first pre-war continuation car to be produced. Of course, not all of the owners of the originals are happy, but it is a neat idea to produce new old cars. It’s not a new idea, but the range of cars coming to market now is growing.

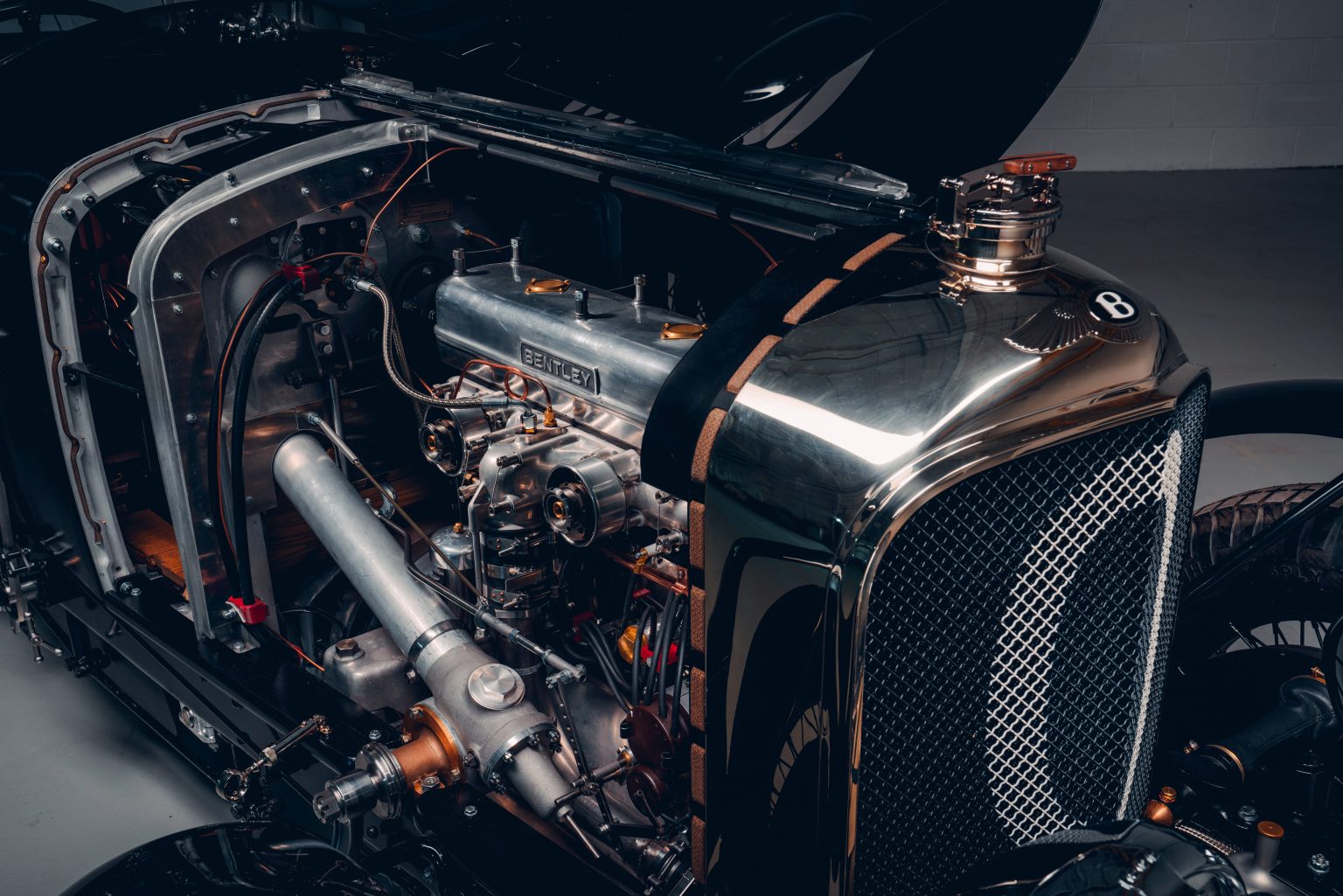

To produce one of the new Bentley continuations takes some 40,000 hours to build. Nearly 2,000 individual components were designed, and hand crafted from original drawings and tooling. In house technicians and British suppliers combined to produce all the required parts.

Bentley own one of the original Blower cars, the ex- Sir Tim Birkin 1929 4 1/2 litre supercharged race car. Chassis HB 3404 with its engine 3902 and registered with the number UU 5872 provided a lot of detail. Every single part was scanned whilst going through a sympathetic restoration.

Using all this new data meant that 1,846 parts were designed to produce the new Blower. 230 of those are assemblies, the largest being the engine.

Car zero is effectively the test and development prototype. Built ahead of the customer cars to go through months of durability and performance testing.

Finished in gloss black paintwork with Oxblood red interior from Bridge of Weir.